5 Proven Steps in Electronic Product Design That Drive Success

5 Proven Steps in Electronic Product Design That Drive Success

Turning an innovative idea into a successful electronic product requires more than just technical skills—it demands a structured approach that many designers and engineers learn through costly trial and error.

This guide walks hardware engineers, product managers, and electronics entrepreneurs through five proven steps in the electronic product design process that separate market winners from expensive failures. You'll discover how to define product requirements that actually matter to customers, develop a system architecture that won't trap you in redesign cycles, and create prototypes that reveal critical issues before they become costly problems.

We'll cover the complete product development lifecycle, from initial concept through market launch, focusing on practical strategies that reduce time-to-market and avoid common pitfalls. You'll learn proven techniques for component selection that balance performance with cost, design for manufacturing principles that prevent production headaches, and quality assurance methods that protect your reputation.

Whether you're launching your first electronic product or looking to streamline your current development process, these steps provide a roadmap for consistent success in today's competitive electronics market.

Define Clear Product Requirements and Market Needs

Conduct Thorough Market Research to Identify Target Audience Pain Points

Understanding your target market forms the backbone of any successful electronic product design process. Start by diving deep into customer forums, social media groups, and industry publications where your potential users discuss their challenges. Direct surveys and interviews with real users reveal gaps that competitors haven't addressed yet.

Focus on identifying specific problems that keep your target audience awake at night. Are they struggling with battery life? Do existing solutions break too easily? Is setup too complicated for non-technical users? Document these pain points with concrete examples and frequency of occurrence.

Competitive analysis reveals what's already available and where opportunities exist. Create a detailed comparison matrix showing features, pricing, user ratings, and common complaints for existing products. This research phase often uncovers underserved market segments or feature combinations that nobody has perfected yet.

Establish Measurable Performance Specifications and Technical Constraints

Transform your market research findings into specific, measurable requirements that guide your electronic product development. Instead of vague goals like "good battery life," define exact metrics such as "minimum 8 hours continuous operation" or "standby time exceeding 30 days."

Technical constraints shape your hardware design methodology from the start. Consider environmental factors like operating temperature ranges, humidity tolerance, and shock resistance requirements. Regulatory compliance requirements vary by market - CE marking for Europe, FCC certification for the US, and specific safety standards for your product category.

Create a requirements traceability matrix linking each specification back to identified user needs. This documentation becomes invaluable during design reviews and helps prevent scope creep. Include both functional requirements (what the product must do) and non-functional requirements (how well it must perform).

| Specification Type | Example Requirements | Success Criteria |

|---|---|---|

| Performance | Response time < 100ms | User testing validation |

| Environmental | -10°C to 60°C operation | Lab testing results |

| Regulatory | FCC Part 15 compliance | Certification approval |

| User Experience | Setup time < 5 minutes | Beta user feedback |

Create Detailed User Personas and Usage Scenarios

Develop comprehensive user personas that go beyond basic demographics. Include technical comfort levels, typical environments where they'll use your product, and their decision-making processes. A persona for a medical device user differs dramatically from one targeting gaming enthusiasts.

Map out realistic usage scenarios that cover both typical and edge cases. Consider how your product fits into users' daily routines. Will they use it while commuting? In professional settings? At home during family time? Each scenario reveals different design requirements and potential failure points.

Document the user journey from initial product discovery through long-term use. Identify touchpoints where users might get frustrated or where your product can exceed expectations. These insights directly influence your product design requirements and help prioritize features during development.

Set Realistic Timeline and Budget Parameters

Break down your product development lifecycle into distinct phases with specific milestones and deliverables. Factor in time for multiple prototype iterations, regulatory testing, and manufacturing setup. Most teams underestimate the time needed for compliance testing and tooling preparation.

Budget planning requires balancing component costs, development expenses, and manufacturing investments. Component selection decisions made early in the design process significantly impact final product costs. Research current market prices for key components and factor in potential supply chain disruptions.

Consider the total cost of ownership throughout the product development lifecycle. Development costs include engineering time, testing equipment, regulatory compliance, and intellectual property protection. Manufacturing costs encompass tooling, assembly, quality control, and packaging. Marketing and support costs continue long after launch.

Risk assessment helps set realistic expectations and contingency plans. Supply chain dependencies, technology maturity levels, and team experience all influence timeline and budget accuracy. Building buffer time into your schedule prevents rushed decisions that compromise product quality.

Develop Strategic System Architecture and Component Selection

Design Modular System Architecture for Scalability and Maintenance

Creating a well-thought-out system architecture forms the backbone of any successful electronic product design process. Breaking your product into distinct, interconnected modules allows for easier troubleshooting, faster development cycles, and smoother future enhancements. Think of each module as a self-contained unit that performs specific functions while communicating with other modules through standardized interfaces.

Start by identifying the core functional blocks of your product. These might include power management, signal processing, user interface, communication, and control systems. Each block should have clearly defined inputs, outputs, and responsibilities. This approach makes your hardware design methodology more systematic and reduces the complexity of managing multiple components simultaneously.

Standardized interfaces between modules become crucial for maintaining flexibility. Whether you're using I2C, SPI, UART, or custom protocols, consistency in communication methods allows you to swap out modules without redesigning the entire system. This modular approach also enables parallel development, where different teams can work on separate modules simultaneously without stepping on each other's toes.

Documentation plays a vital role in modular design. Create detailed interface specifications for each module, including electrical characteristics, timing requirements, and communication protocols. This documentation becomes invaluable during maintenance phases and when bringing new team members up to speed on the product design requirements.

Select Optimal Components Based on Performance, Cost, and Availability

The component selection process directly impacts your product's success in the market. Smart component choices balance performance requirements with cost constraints while ensuring long-term availability. Start by creating a comprehensive component database that tracks key parameters like specifications, pricing trends, lead times, and supplier reliability.

Performance evaluation should go beyond basic specifications. Consider real-world operating conditions, temperature ranges, power consumption patterns, and electromagnetic compatibility. Many components look perfect on paper but struggle in actual deployment scenarios. Always factor in tolerance variations and worst-case operating conditions when making selections.

Cost analysis requires looking beyond the initial component price. Consider the total cost of ownership, including assembly complexity, testing requirements, and potential failure rates. A slightly more expensive component with better reliability might save money in the long run through reduced warranty claims and support costs.

| Component Category | Key Selection Factors | Cost Considerations |

|---|---|---|

| Microcontrollers | Processing power, peripherals, development ecosystem | Unit price, development tools, time-to-market |

| Power Management | Efficiency, thermal performance, regulation accuracy | Component cost, cooling requirements, battery life |

| Sensors | Accuracy, noise performance, calibration needs | Initial cost, calibration equipment, maintenance |

| Connectors | Durability, signal integrity, environmental rating | Material cost, assembly complexity, failure rates |

Supply chain stability has become increasingly important in recent years. Diversify your supplier base and maintain relationships with multiple distributors. Consider second-sourcing critical components early in the design phase, even if it means additional qualification work upfront.

Plan for Future Upgrades and Feature Expansions

Building upgrade paths into your electronic product development strategy from the beginning saves significant time and resources later. Reserve extra GPIO pins, include unused memory space, and design power supplies with headroom for additional features. These small investments during initial design pay huge dividends when market demands evolve.

Hardware versioning strategy should account for both incremental improvements and major feature additions. Design your PCB layout with expansion areas and consider using modular connector systems that allow plug-in feature cards. This approach enables you to add new capabilities without complete redesigns.

Software architecture must align with hardware expandability. Implement modular firmware structures that can accommodate new features through updates or plug-in modules. Reserve memory space for future functionality and design your communication protocols to handle new message types and extended feature sets.

Consider the product development lifecycle when planning upgrades. Some features might require hardware changes, while others can be delivered through firmware updates. Plan your upgrade release schedule to align with manufacturing cycles and market windows. This strategic approach to upgrades can extend product life and create new revenue streams from existing customers.

Future-proofing also means anticipating technology shifts. Reserve space and power budget for emerging connectivity standards, newer sensor technologies, or enhanced processing capabilities. While you can't predict every technological advancement, building flexibility into your design helps your product adapt to changing market conditions.

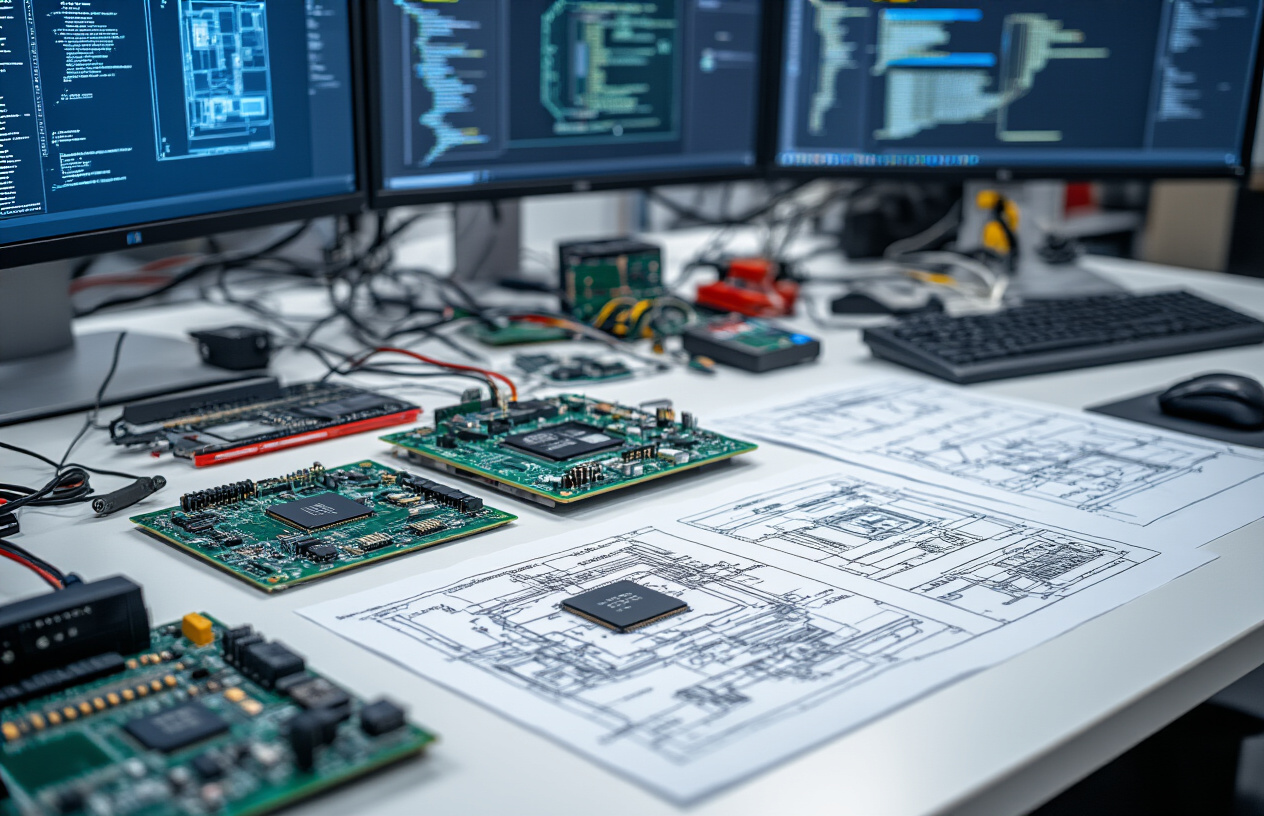

Create Comprehensive Prototypes and Validation Testing

Build functional prototypes to verify core concepts

Building functional prototypes marks a critical turning point in the electronic product design process. This phase transforms theoretical concepts into tangible hardware that validates your design assumptions and reveals potential issues before they become costly problems.

Start with rapid prototyping techniques that allow quick iteration cycles. Breadboards work well for initial circuit validation, while printed circuit board (PCB) prototypes provide more realistic performance characteristics. 3D printing enables fast mechanical enclosure testing, letting you evaluate form factor decisions and user interaction patterns.

Focus on creating prototypes that test specific functionality rather than building complete systems from the start. Break complex designs into modular components that can be validated independently. This approach accelerates development timelines and makes troubleshooting more manageable when issues arise.

Document every prototype iteration meticulously. Track component specifications, circuit modifications, and performance measurements. This documentation becomes invaluable when scaling to production and helps team members understand design evolution over time.

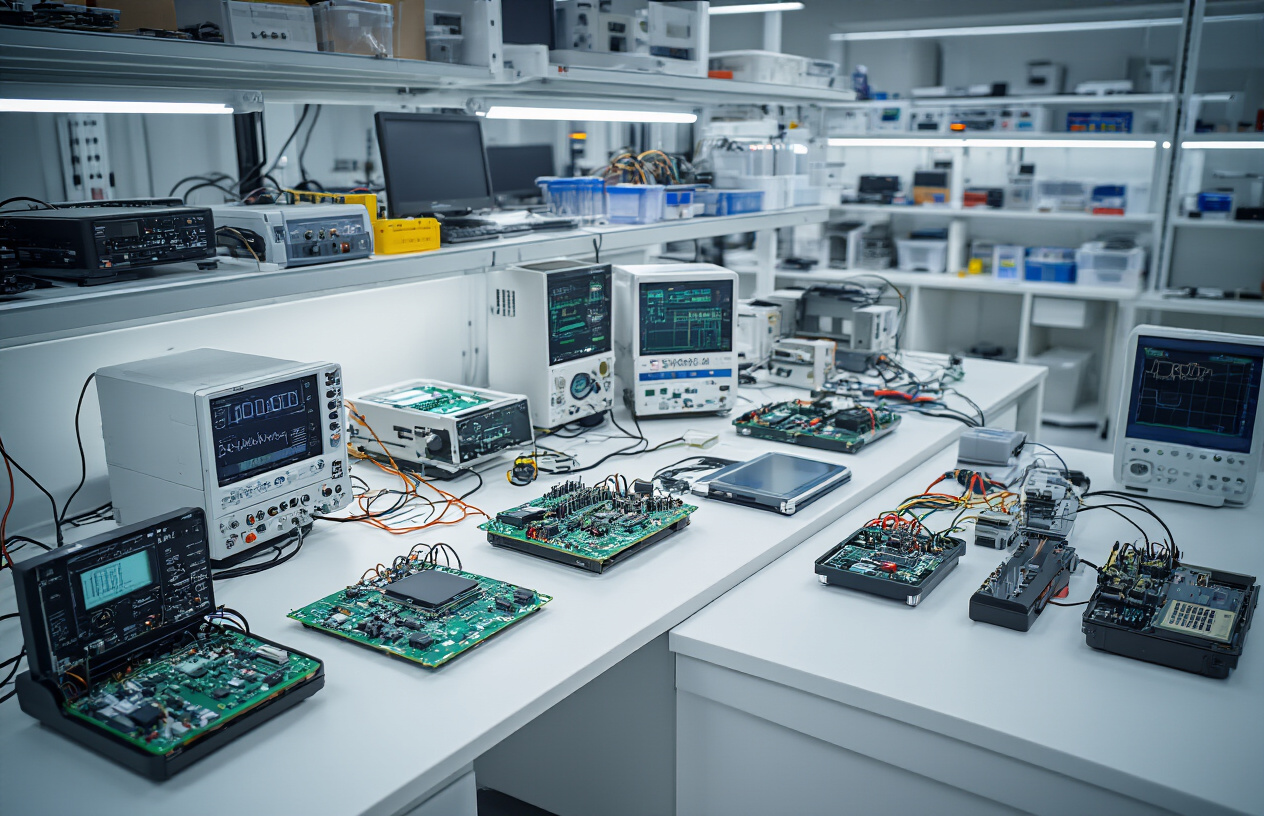

Conduct rigorous performance testing under real-world conditions

Laboratory testing only tells part of the story. Real-world performance testing exposes your prototype development to environmental stresses, user behaviors, and operational scenarios that controlled environments cannot replicate.

Create test protocols that mirror actual usage patterns. If designing a portable device, test battery performance across various usage scenarios and ambient temperatures. For industrial equipment, simulate the electromagnetic interference and vibration conditions found in manufacturing environments.

Environmental stress testing should cover temperature extremes, humidity variations, shock resistance, and electromagnetic compatibility. These tests often reveal design weaknesses that would otherwise surface after product launch, when fixes become exponentially more expensive.

Power consumption testing deserves special attention in modern electronic product development. Measure current draw across all operating modes, including sleep states and peak performance scenarios. Battery life projections must account for component aging and real-world usage variability.

Gather user feedback through structured testing sessions

User feedback sessions provide insights that engineering teams often overlook. Technical teams focus on functionality, but users care about usability, aesthetics, and how products fit into their daily workflows.

Structure testing sessions with clear objectives and measurable outcomes. Prepare specific tasks for users to complete while observing their interactions with your prototype. Note where users hesitate, struggle, or express confusion about interface elements or physical controls.

Record both quantitative and qualitative feedback. Time how long users take to complete common tasks, but also capture their emotional responses and suggestions for improvement. Sometimes the most valuable insights come from casual comments users make during testing breaks.

Mix your test participant demographics to capture diverse perspectives. Age, technical experience, and cultural background all influence how people interact with electronic products. A control interface that seems intuitive to engineers might confuse typical end users.

Iterate designs based on validation results

Validation results drive design refinements that separate successful products from market failures. Establish clear criteria for what constitutes acceptable performance before testing begins, then stick to these standards when evaluating results.

Prioritize issues based on their impact on user experience and safety. Critical failures that affect core functionality demand immediate attention, while cosmetic issues can be addressed in later iterations. Create a structured process for evaluating and implementing changes to avoid endless revision cycles.

Track the effectiveness of each design change through subsequent testing rounds. Some modifications might solve one problem while creating another, making systematic validation essential for maintaining overall product quality.

Budget time and resources for multiple iteration cycles. First prototypes rarely meet all requirements, and rushing to production without adequate validation increases the risk of expensive recalls or market rejection.

Perform compliance and safety standard assessments

Compliance testing ensures your product meets regulatory requirements in target markets. Different regions have varying standards for electromagnetic compatibility, safety, and environmental impact, making early assessment crucial for avoiding launch delays.

Engage with certified testing laboratories early in the prototype development phase. These facilities can provide preliminary assessments that identify potential compliance issues before formal certification testing. This proactive approach saves significant time and money compared to discovering problems during final certification.

Safety standards vary significantly across product categories. Medical devices face stricter requirements than consumer electronics, while industrial equipment must meet different safety criteria than residential products. Research applicable standards thoroughly and design compliance measures into your hardware design methodology from the beginning.

Document all compliance testing activities and maintain detailed records of test results. Regulatory authorities may request this documentation during product approval processes, and having organized records demonstrates due diligence in product safety considerations.

Optimize Design for Manufacturing and Cost Efficiency

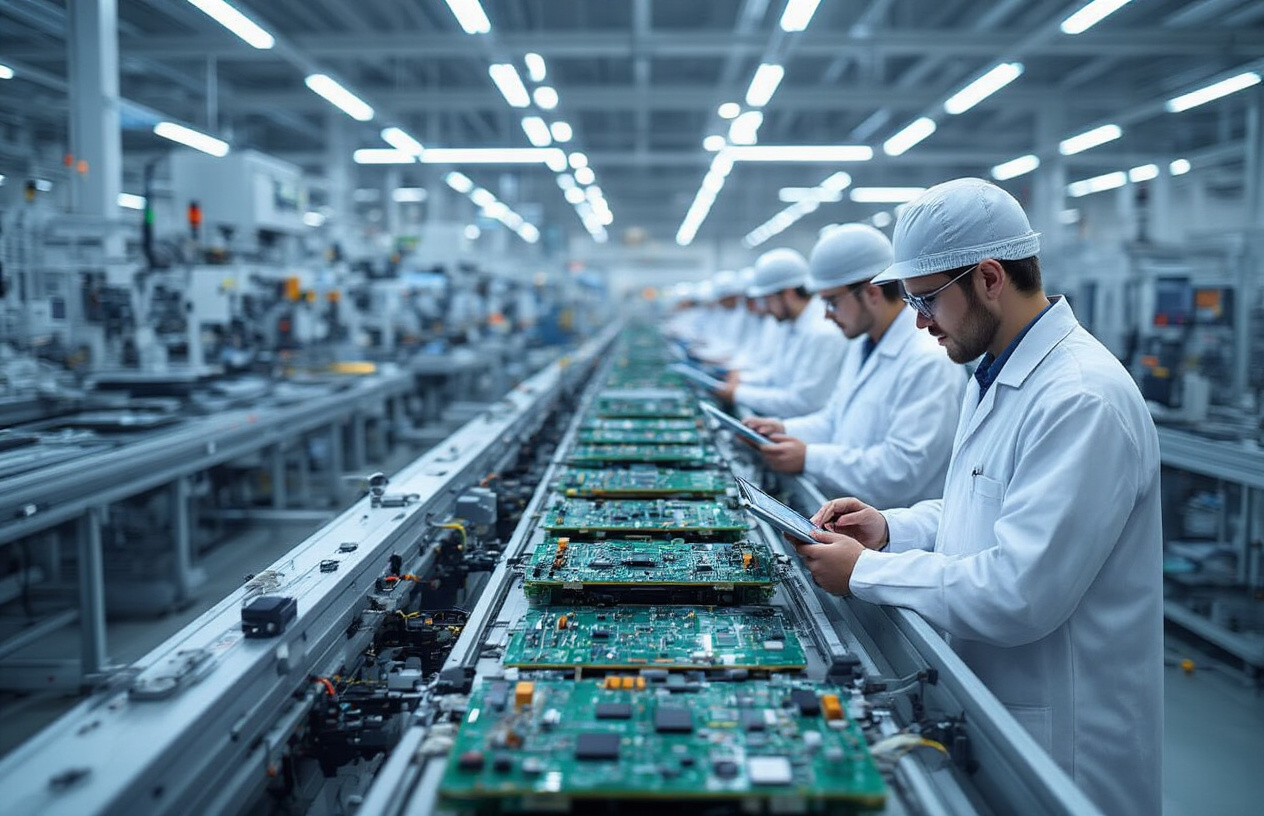

Collaborate with manufacturing partners early in the design process

Getting manufacturing partners involved from day one makes the difference between a smooth product launch and a nightmare of delays and cost overruns. When engineers work in isolation, they often create designs that look perfect on paper but become expensive headaches in the real world.

Smart electronic product design teams bring manufacturers to the table during the initial architecture phase. These partners understand the practical limitations of their equipment, tooling capabilities, and material handling processes. They can spot potential assembly issues before they become costly problems.

Manufacturing partners provide valuable insights about component availability, lead times, and cost fluctuations. A resistor that costs pennies in small quantities might become unavailable or expensive when you need 100,000 units. Early collaboration helps identify these risks and develop backup plans.

The partnership goes both ways. Design teams share their vision, performance requirements, and target costs, while manufacturers explain their constraints and suggest alternatives. This back-and-forth creates designs that balance performance with production reality.

Consider establishing formal design review checkpoints with manufacturing partners. Schedule these reviews at 25%, 50%, and 75% design completion to catch issues before they're expensive to fix. Document these discussions and incorporate feedback into design revisions.

Minimize component count and simplify assembly procedures

Every component in an electronic product represents multiple cost factors: the part itself, handling time, potential failure points, and inventory management. Experienced designers obsess over component count reduction because it directly impacts both manufacturing costs and product reliability.

Start by questioning every component's necessity. Can two functions be combined into a single integrated circuit? Can standard resistor networks replace individual resistors? Modern microcontrollers often include features like analog-to-digital converters, timers, and communication interfaces that eliminate the need for separate chips.

Assembly procedures become exponentially more complex as component count increases. Each additional part requires placement time, soldering operations, and quality inspection. Surface-mount components generally allow for faster automated assembly compared to through-hole parts, but design teams must balance this against other factors like repairability and thermal management.

Component standardization across product lines creates economies of scale. Using the same capacitor values, connector types, and integrated circuits across multiple products reduces procurement costs and simplifies inventory management. This strategy also makes it easier for manufacturing partners to maintain expertise with specific components.

Create assembly drawings that show the logical sequence of component placement. Group components by assembly method - all surface-mount parts first, then through-hole components, followed by larger mechanical assemblies. This approach minimizes handling and reduces the chance of assembly errors.

| Assembly Method | Typical Cost per Component | Speed (parts per minute) | Accuracy |

|---|---|---|---|

| Manual placement | $0.15-0.30 | 100-300 | 95-98% |

| Pick-and-place | $0.05-0.15 | 5,000-20,000 | 99.5%+ |

| Wave soldering | $0.02-0.08 | N/A (batch process) | 98-99% |

Design for automated production and quality control

Modern electronic manufacturing relies heavily on automated equipment to achieve the speed, consistency, and cost targets that competitive markets demand. Designs that accommodate automated production typically cost 30-50% less to manufacture than those requiring extensive manual intervention.

Automated pick-and-place machines have specific requirements for component orientation, spacing, and accessibility. Components need adequate clearance for the placement head to approach without interference from nearby parts. Standard component orientations and packaging help machines operate at maximum speed without programming complications.

Quality control becomes more critical and more achievable with proper design for automation. Automated optical inspection (AOI) systems can verify component placement, solder joint quality, and polarity orientation, but they need clear sight lines and consistent lighting conditions. Reflective components or awkwardly positioned parts can confuse these systems.

Test point accessibility enables automated in-circuit testing (ICT) and functional testing. Design test points with standard spacing and heights to accommodate test fixture probes. Position these points away from components that might interfere with probe contact.

Panelization strategies significantly impact automated production efficiency. Multiple circuit boards arranged in a single panel move through assembly equipment together, reducing handling time per unit. Standard panel sizes that match your manufacturing partner's equipment maximize throughput.

Consider the entire automated workflow from component placement through final testing. Each step should flow logically to the next without requiring board rotation, special fixtures, or manual intervention. This holistic approach to design for manufacturing creates products that can be built quickly, consistently, and cost-effectively at scale.

Execute Quality Assurance and Market Launch Preparation

Implement Comprehensive Testing Protocols for Production Units

The shift from prototype to production represents a critical juncture in the electronic product design process. Production testing goes beyond the validation testing performed on prototypes - it requires systematic protocols that can scale with manufacturing volumes while maintaining quality standards.

Start by developing automated test equipment (ATE) that can efficiently verify functionality, performance, and safety parameters for every unit. Your testing protocol should include functional tests that verify all features work as intended, parametric tests that confirm electrical specifications fall within acceptable ranges, and environmental stress screening to identify early failures.

Consider implementing boundary scanning for complex circuit boards, which allows testing of interconnections without physical access to every pin. For wireless products, establish radio frequency testing procedures that verify transmission power, frequency accuracy, and spurious emissions compliance. Create pass/fail criteria that are clearly defined and measurable, leaving no room for subjective interpretation during production.

Build in statistical process control methods to track test results over time. This data reveals trends that might indicate component aging, manufacturing drift, or other issues before they become widespread problems. Establish correlation between your production tests and field reliability data to continuously refine your testing approach.

Develop User Documentation and Support Materials

User documentation often receives insufficient attention during the electronic product development lifecycle, yet it significantly impacts customer satisfaction and support costs. Start creating documentation during the design phase rather than treating it as an afterthought.

Develop multiple layers of documentation to serve different user needs. Quick start guides should get users operational within minutes, focusing on the most common use cases. Comprehensive user manuals should cover all features, troubleshooting procedures, and technical specifications. Create video tutorials for complex setup procedures or advanced features that benefit from visual demonstration.

Your support materials should anticipate common questions and problems. Analyze feedback from beta testing and early adopters to identify pain points that documentation can address. Build a knowledge base that includes frequently asked questions, troubleshooting flowcharts, and solution articles for known issues.

Consider the international market early by designing documentation that translates well. Use clear diagrams, standardized symbols, and concise language that reduces translation complexity and costs. Develop templates and style guides that ensure consistency across all materials.

Create Go-to-Market Strategy and Distribution Channels

Your go-to-market strategy must align with both your product capabilities and target market expectations. Research shows that 70% of electronic products fail not due to technical issues, but because of inadequate market positioning and distribution planning.

Identify the most effective channels for reaching your target customers. Direct-to-consumer sales offer higher margins but require significant marketing investment and customer acquisition costs. Retail partnerships provide broader reach but demand competitive pricing and marketing support. Online marketplaces offer quick market entry but intense price competition.

Develop pricing strategies that account for all channel requirements, including distributor margins, marketing costs, and support expenses. Create different product configurations or bundles for different channels to minimize direct price competition between your distribution partners.

Build relationships with key opinion leaders and industry influencers who can provide credible product endorsements. Plan your launch timeline to coincide with industry events, seasonal buying patterns, or complementary product releases that can amplify your market impact.

Establish Post-Launch Monitoring and Improvement Processes

Successful electronic product launch preparation extends well beyond the initial market introduction. Establish monitoring systems that track product performance, customer satisfaction, and market reception from day one.

Implement field failure reporting systems that capture detailed information about product issues, usage patterns, and environmental conditions. This data becomes invaluable for future product iterations and can identify opportunities for immediate improvements through firmware updates or revised user guidance.

Create feedback loops with customer support teams, sales partners, and end users. Regular review meetings should analyze support ticket trends, customer complaints, and feature requests to prioritize product enhancements. Set up metrics that track key performance indicators like return rates, customer satisfaction scores, and repeat purchase rates.

Plan for ongoing product evolution through regular firmware updates, accessory releases, or complementary products that extend the platform's capabilities. The most successful electronic products treat launch as the beginning of a continuous improvement cycle rather than a final milestone.

Getting your electronic product design right comes down to mastering these five essential steps. Clear product requirements give you direction, smart system architecture builds a solid foundation, thorough prototyping catches problems early, manufacturing optimization keeps costs under control, and quality assurance ensures your product succeeds in the market. Each step builds on the previous one, creating a roadmap that reduces risks and increases your chances of success.

Don't skip any of these phases, even when deadlines are tight or budgets are stretched thin. Companies that rush through requirements or cut corners on testing often end up spending far more money fixing problems later. Start with your first step today – define exactly what your product needs to do and who will use it. With these proven steps as your guide, you'll be well on your way to launching an electronic product that customers actually want and that delivers real value to your business.